Presenting at the 42nd International Symposium for Testing and Failure Analysis (ISTFA 2016)

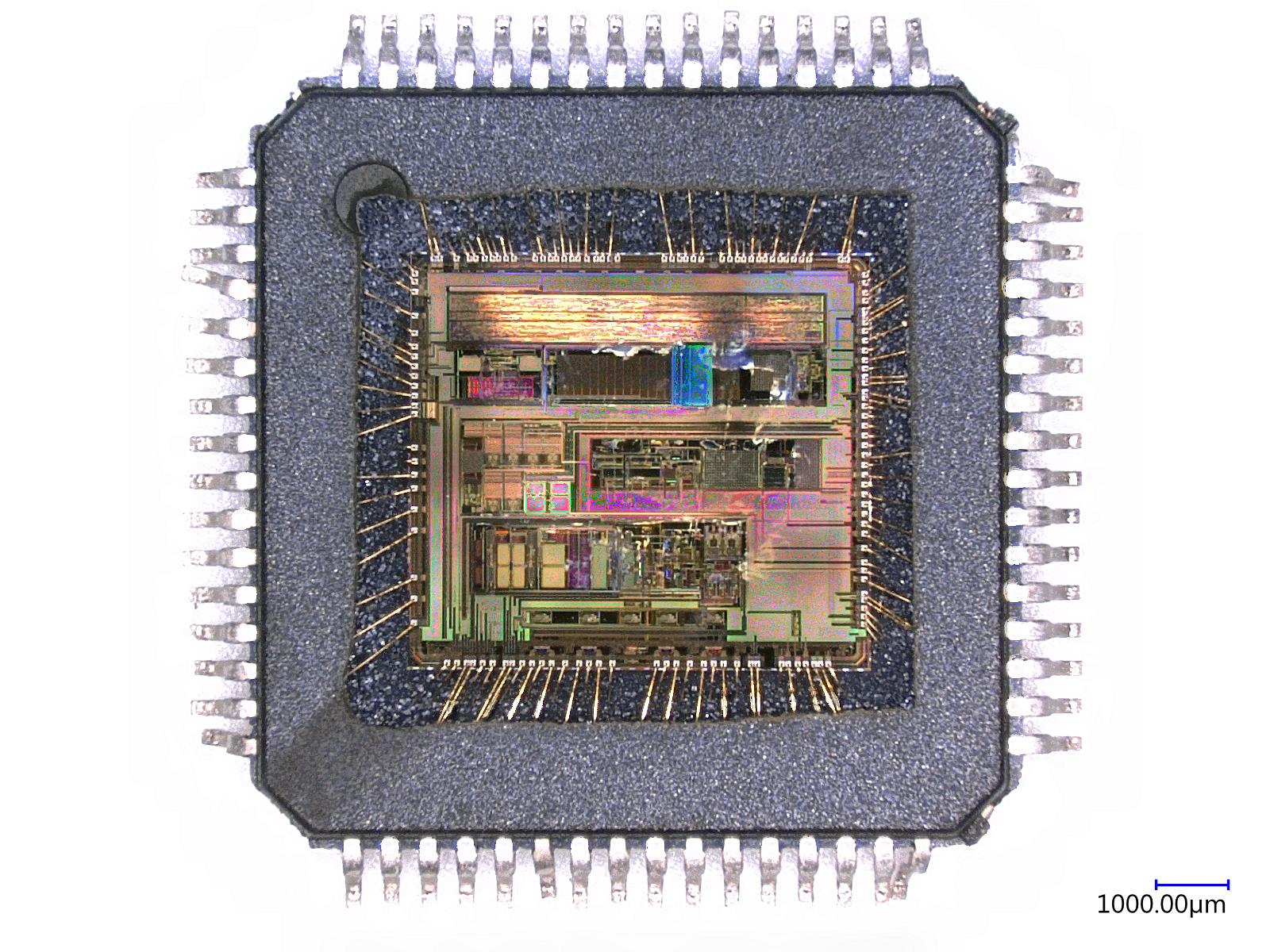

One of my main areas of study as a laser application scientist with Control Laser Corporation is in perfecting the process of laser decapsulation of semiconductors. As my entire life has revolved around semiconductors, and the electronics industry in general, this work is right up my alley, as we say. I work with some of the greatest minds of our time in this industry to both help them understand laser decapsulation as well as to learn from them the latest trends in semiconductor packaging so that my company can continue to innovate in this realm. It is exciting work!

For many years, hazardous chemicals have been used to remove the mold compound from semiconductors leading environmental issues as the used chemicals need to be disposed of somehow. There has been a huge shift in the industry to move away from chemicals where possible to mitigate such environmental issues. Laser decapsulation of semiconductor mold compound offers an alternative; however, the method is only now allowing the use of the laser to fully decapsulate some semiconductors without the need to process the chip through a secondary chemical process.

This year, with a partner-customer of Control Laser, Infineon Technologies, I will be presenting a tutorial on the latest research in laser decapsulation. The title of our paper is Effective Laser Decapsulation Employing the Digital ICO Laser and HAZ-Methodology. As of now, it is scheduled to be presented on November 8, 2016 at 1:30pm.

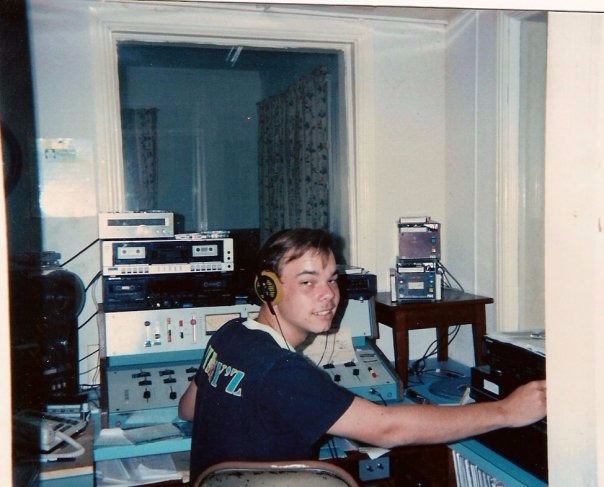

I am very excited about this presentation. As an autodidact, this presentation is another level of achievement in my career. To look back at where I once was, to where I am now, is just astonishing to me. To think that enough people in my career path have recognized my skills and not only allowed me, but paid me, to do what I am doing makes me feel better about the possibilities of those of us who didn’t have the structure in life, nor the financing, to get a formal education. What this means is that if you work hard enough on something–I have been studying electronics since age 14–then you will eventually get somewhere; the investment will eventually pay off. Don’t give up!

Nothing in this post, or this website, is meant to convey the opinions or views of Control Laser Corporation, or Infineon Technologies.

It all started when I watched my dad fix a very expensive RC car after I ran it to death, when I was a kid.

2 Responses

Congrats on your achievement! The laser field is awesome and its great that you started a business from what you like to do! Was it difficult to get started in such a challenging field?

Hi Galen,

Thank you very much. I’m actually an employee at a laser company, rather than owning the company myself. I wish I owned the company! lol

To your question: It’s all relative, I think. Some people go to college and they see the many years of dedication to that education to be difficult. I never had the opportunity to go to college, and I’m not sure that I would be very good at it if I did go, but I studied religiously on my own for 10-years before I got my first job as an electronics technician, later an electronics engineering technician, and now a laser application scientist. That wasn’t difficult; I was, and am, very happy and very eager to learn about technology in general. It was, and is, so much fun! But the difficult part for me came when convincing my former and current boss that I could do whatever they needed as it applies to technology. In terms of my current boss, at the laser company, they needed someone with a hardware and software background; I was told that they would teach me everything that I needed to know about lasers, and they did. They sent me to one of the renown laser companies, now defunct, Quantronix, where I took three different courses in laser technology from their laser scientists. It was an insane amount of information condensed into very short classes and I picked up a few books on the subject as well to supplement the training. As I had a good understanding of semiconductors I was made the lead for the semiconductor laser systems. I visited labs at some of the largest semiconductor companies and I developed business relationships out of those visits. Now, many years later, I have a very good rapport with people in labs all over the country and we work together to come up with new solutions to new problems, particularly in the failure analysis of semiconductors. I love every minute of this. The saying is true: if you love what you do you will never work a day in your life. If I had to add to that I would say that you also need to convince yourself that you can do whatever you put your mind to. That’s not so easy when there are so many in this world who, out of perhaps jealousy, or lack of confidence in themselves to do the same things, will become naysayers. Once you convince yourself that you can do something, you surround yourself with people whom are also convinced in their abilities to do something, and can contribute to your mutual cause. I’m not saying that going to college is a bad thing, some people need more of a structured environment to learn, but I can’t stand that. I work better when I have a topic to focus on, which ultimately has some useful purpose in this world.

So, the bottom line is, I think, that each day moving forward is easy, but looking back at all that work I had to do to get to this point in my life appears to be very difficult. Just find something you love and run with it. You will never be bored and you will love every minute of your life, which I think is the most important thing of all.